The Hard Life of Water Softener Resin

Is your Water Softener still removing sufficient hardness, or do you see water spots or scale? Is water pressure still adequate, or does it seem lower than it used to? Do you feel like you run out of soft water in between cycles?

If you answered yes to any of these problems, your water softener resin may be worn out.

So what is “Water Softener Resin”, why does it wear out, and how long does it last?

Magic Little Beads

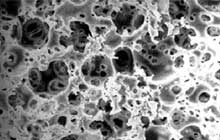

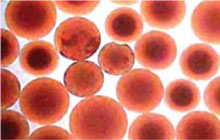

Water Softeners use “Ion Exchange Resin Beads” that are little spheres that range from 0.3-1.2mm in size.

These beads are made by combining strands of Polystyrene which are wrapped around in a crisscross fashion, along with Divinylbenzene (DVB) which acts like a glue that holds the resin together.

The number of “links” in the bead will determine its strength, and how long it lasts.

Most modern water softeners use 8% crosslink resin. A few High Performance Water Softeners use 10% crosslink resin, which has more “links in the chain” to increase durability.

How Do Resin Beads Work?

The crosslink structure contains negatively charged “exchange sites” that hold sodium ions. As water travels through the softener, positively charged ions like Calcium, Magnesium, and Iron will stick to the exchange sites on the bead.

As the Hard Water Ions “stick” to the bead, the sodium ions are knocked off the bead, and into the water supply. Once the resin bead is loaded up, the softener must regenerate the beads with more sodium to continue working.

Iron Damage to Resin

Well Water in our area can have extremely high Iron levels, and most City Water sources still have low levels of Iron – even after going through the water treatment plant.

It takes 4x more sodium to clean iron off of a Resin Bead than it takes to remove Calcium or Magnesium.

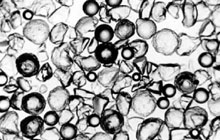

If the iron is not THOROUGHLY cleaned off the bead, oxygen in the water oxidizes the Iron molecule causing it to grow roughly 20x in size. When this happens, the Resin Bead plugs up and loses a majority of its capacity.

Chlorine Damage

Chlorine is a great disinfectant that many cities use to control bacteria. It’s also a powerful oxidizer that affects rubber and plastic (like resin!).

Chlorinated water oxidizes and destroys Divinylbenzene (DVB) which is the crosslinking agent that gives beads their physical strength. Once the DVB bond is broken, the bead swells, and turns into a useless gel-like mass.

Here’s how you can predict chlorine’s effect on standard 8% resin life:

10/ parts-per-million (ppm) of chlorine = the expected years of service

At 0.5ppm chlorine, this is 20 years. At 2ppm, it is only five years.

Resin Takes a Beating – Literally

Water weighs 8.3 pounds per gallon. It can move through your plumbing at 8 feet per second.

Now imagine you’re running water at the bathroom sink, and you turn the water off. You don’t SLOWLY turn off the water. You pull the handle, and the water stops – quickly.

When flowing water stops immediately, it creates a shock wave that travels back through the plumbing system and SLAMS into the resin bed.

This slamming effect is called hydraulic shock. This “water hammer” physically cracks the plastic resin beads into little “fines” that eventually get flushed down the drain when the softener regenerates.

How Long Do Resin Beads Last?

Resin life is determined by a combination of the factors we discussed: the % crosslink in the bead, iron damage, chlorine damage, and hydraulic shock.

Depending on these conditions, standard 8% resin will breakdown 2-10% each year.

Besides removing chlorine or iron, you can also improve resin life by increasing the crosslink %.

Summary: When does Water Softener Resin need Replacement?

As resin breaks down, it releases fines that plug up the softener and result in a pressure drop. As it plugs up with iron, or oxidizes by chlorine, you lose capacity.

Lower capacity means more frequent regenerations which wastes water and salt.

If you used to regenerate every four days, it might be every three. Or maybe your hardness setting was at 15gpg, and now you have it set at 40gpg.

Instead of limping along with low water pressure, and wasting water and salt – its time to replace the resin! If the controls on the machine are old and outdated, sometimes it makes more sense to upgrade to a more efficient water softener.

If you’re having any of these problems with your current system, we offer a FREE Service Inspection to help you find out what your options are.

My brrother suggested I might like this blog.

He was totally right. This post truly made my

day. You can not imagine just how much time I had spent for this info!

Thanks!

Hi, PremierWater,

My well water has three issues: 1) high silt, 2) 500 tds/ppm of hardness, 3) I highly suspect high concentration of IRON.

While the first two issues are now addressed properly, I do not know how to take out the iron from water. Is there a special media used other than carbon and anthracite (still basically carbon)?

You should get the iron level tested. Hard to say without knowing that.

Also good to check ph, manganese, iron bacteria, and tannins.

Lots of good options, but you need to know those things to pick the best one for your needs.

Thanks for posting!

I have a salt free softener which uses caltrite to lower the ph in the water. My pressure has dropped and my plumber wants to charge me $400.00. I would like to try flushing it out myself to save money. Questions are, do I need to replace the caltrite If so where can I buy it? Also, do I have to change out the riser with the filter attached to the bottom?

Do you mean calcite? That would raise the pH. That media tends to pack up if not backwashed properly.

You can buy loose media, and replace yourself – if you can get it out.

Calcite turns into cement over time, and you may need to replace the entire tank.

I was looking for answers to how long the resin would last. I have a new (2 years old) Culligan HE model water softener and the resin already needs changing. That just doesn’t seem right to me. What would cause such rapid breakdown. I’m using the city water supply which fills my water tanks and then through the softener. The water supply is erratic so when there is water in the mains it feeds directly through the softener. Two years for a system that is supposed to be quite good can’t be right.

Any suggestions as to what may cause this?

Culligan doesn’t specify the % crosslink of their resin. 8% is industry standard, but it should last much longer than 2 years. Heavy chlorine, high iron, high water pressure, and/or misuse/misapplication would contribute to a shorter service life. 2 years is still pretty short. Good luck with your service, and thanks for posting!

I checked the Chlorine PPM with information supplied by the county where I live (Pinellas, FL). If I’m reading the data correctly, the Chlorine PPM average is 3.7 I’m calculating this to 2.7 years of life for my resin. Is this correct?

3.7ppm is very high compared to most municipalities in the Twin Cities. I wouldn’t expect more than 5 years of good performance. I would definitely install a carbon filter first.

Thanks for posting!

Lars

I live in Seminole and have a Culligan too. Yes the chlorine is published at 3.7ppm, I get about 5 years out of resin. You can put carbon filter before softener and it should help.